Evaluation of concrete quality in deep foundations by the Crosshole Sonic Logging method (CSL)

Have a technical question? Ask our team of engineers.

Request a quoteThe Cross-Hole Analyzer evaluates the quality of the concrete of deep foundations by the Crosshole Sonic Logging (CSL) method. It also performs Single Hole Sonic Logging (SSL).

The CHAMP-XV consists of a main unit with 60 GB internal solid state drive (SSD) and Windows 7 OS, a receiver and a transmitter in sturdy brass housing, two independent depth measuring devices, a tripod for assembling the test, and the powerful software CHA-W. Options include the Motorized Probe Deployment System that relieves the operator from pulling the cables manually, making testing more comfortable and the PDI-TOMO software.

Drilled shafts and other cast-in-place concrete foundations are prepared for the test by installation of PVC or steel tubes during their construction. During the test, a transmitter is lowered down one of the tubes and sends a high-frequency signal to a receiver inserted in another tube. Transmitter and receiver move down each pair of tubes, scanning the entire length of the shaft. Cables for the receiver and transmitter are available in various lengths, and may each be positioned at different depth levels for maximum testing flexibility.

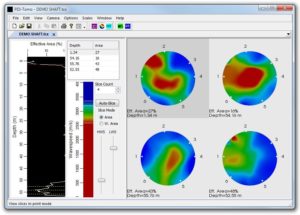

PDI-TOMO

The attractive enclosure of the CHAMP-XV cross-hole analyzer is still light and small, but its color touch-screen display is 5 cm larger than the previous model and visible in all lighting conditions. The replaceable internal battery frees the tester from a power source, allowing easy movement between shafts. This allows for essential analysis to be performed in the field in real time. In addition, data entry is optimized for speed of testing and to minimize erroneous input.

Field data is transferred to a computer through USB ports and further analyzed by the CHA-W software, which outputs graphs such as First Arrival Time, Wave Speed, Waterfall Diagram and Energy Plot, and aids in test report preparation.

The CHAMP-XV meets or exceeds the specifications for cross-hole sonic logging required by D6760 Standard Test Method for Integrity Testing of Concrete Deep Foundations by Ultrasonic Crosshole Testing.

CHA-W processes Cross Hole Analyzer data. Its analysis tools include evaluation of signal strength, the helpful Edge Finder to detect the First Arrival Time (the moment the signal sent by the transmitter first reaches the receiver, also known as FAT) and Defect Analysis, a visual aid for easy defect identification. CHA-W reporting tools comprise user customized graphs and tables.

The mean and standard deviation of the measured wave speed and the location of defect is displayed. Graphs include signal strength versus time and depth (Sonic Map, also called Waterfall Diagram), FAT versus depth, wave speed versus depth and signal strength versus depth.

Main Unit

Physical

Size: 320 x 250 x 68 mm (12.6 x 9.8 x 2.7 in)

Weight: 5 kg (11 lbs.)

Display: 26.4 cm (10.4 in) sunlight readable touch screen display, resolution 1024 X 768

Operating temperature range: 0˚ to 40˚C (32˚ to 104˚F)

Power: 4-hour continuous data collection with internal 12V battery, or 100 – 240 VAC power supply

Charging Time: 6-hours maximum

Electronic

Computer with 60 GB SSD internal drive and 4 external USB ports

12-bit analog to digital (A/D) converter

Sampling rate: 500 kHz, 1 MHz and 2 MHz; user selectable (equivalent measuring accuracy 2μs, 1μs and 0.5μs)

Scan rate: 32 scans/seconds

Record size: 250, 500 and 1000 points, user selectable

User adjustable gain, trigger level and transmit power level

Other

Windows® 7 OS

Operates in English or SI Units

Furnished with CHA-W software

Full one-year warranty

Technical manual provided in PDF form on a USB drive

Probes

Physical

Size: 215 mm length x 25 mm diameter (8.46 in length x .984 in diameter)

Element: Ceramic

Housing: Nickel plated brass

Independent depth encoder for each probe

Maximum measuring distance (probe separation): 3 m (9.84 ft)

Electronic

Receiver: tuned to 45 KHz nominal

Transmitter frequency (nominal): 45 KHz

Transmitter voltage: 200, 400, 600 or 800 Volts; user selectable

Cables

Cable material: heavy duty polyurethane outer jacket

Cable length: 60, 100 or 150 m (196, 328, 492 ft)

Cables spooled over tripod (standard) or with optional Motorized Probe Deployment System, only with the 60 m cables (196 ft)

Motorized Probe Deployment System

Main Unit

Size: (2) 380 x 480 x 405 mm spools (14.96 x 18.89 x 15.94 in)

Weight: 11.3 Kg each (24.91 lbs.)

Includes 60 m (196 ft) cable detachable from spool

Includes depth encoder for each probe, attached to frame

Motor Control Unit

Size: 240 x 160 x 90 mm (9.44 x 6.29 x 3.54 in)

Weight: 1.6 Kg

Powered by either external battery (8-hour duration), 12VDC car battery, or 100 – 240 VAC with

12 VDC converter

Fast charger to recharge the external battery in 4 hours

Variable probe pull rate: 0.150 to 0.915 m/sec (low, medium, high speed selection)

Resettable circuit breaker motor protection

Operating temperature range: 0° to 40°C (32° to 104°F)

Storage temperature range: -10° to 65°C (14° to 149°F)

Other

Includes pulley for placement at the tube

Includes roller guide for routing cable through re-enforcement rebar cage or over casing

The CHAMP-XV includes a full warranty and technical support. PDI offers expert training in the use of the CHAMP-XV.

for desktop or laptop only

CHA-W only license

The CHA-W software lock license is not a shared license and only good for one user and on one computer at a time. How you activate the license is by emailing in your site code and we will reply with a site key.

PDI-TOMO/CHA-W license

PDI-TOMO is sold with CHA-W as PDI-TOMO needs CHA-W to run

The PDI-TOMO/CHA-W software lock license is not a shared license and only good for one user and on one computer at a time. How you activate the license is by emailing in your site code and we will reply with a site key.

We offer free license transfers for all single‑user software locks, as long as the original installation is properly deactivated. A valid deactivation code must be provided when moving the license to a new computer.

If a deactivation code cannot be generated due to computer failure, reformatting, or system malfunction, a reactivation fee will be required to issue a new activation.

This policy ensures the protection and proper management of all licensed software.