- Up to 8 data acquisition channels in wired configuration or up to 16 data acquisition channels in wireless configuration

- All data acquisition channels are universal – any sensor type is compatible with any input channel. Ability to connect any combination of strain transducers and accelerometers to any channel (wired or wireless configuration)

- Smart PDA-8G sensors (the PDA-8G identifies the sensor type, serial number, and calibration factor)

- Unified operating system (same software program used on PDA unit and PC)

- Data may be collected at 120 blows per minute (BPM) making it easier to test piles being driven by hydraulic hammers with high blow rates

- PDIPLOT software is integrated into PDA-S software

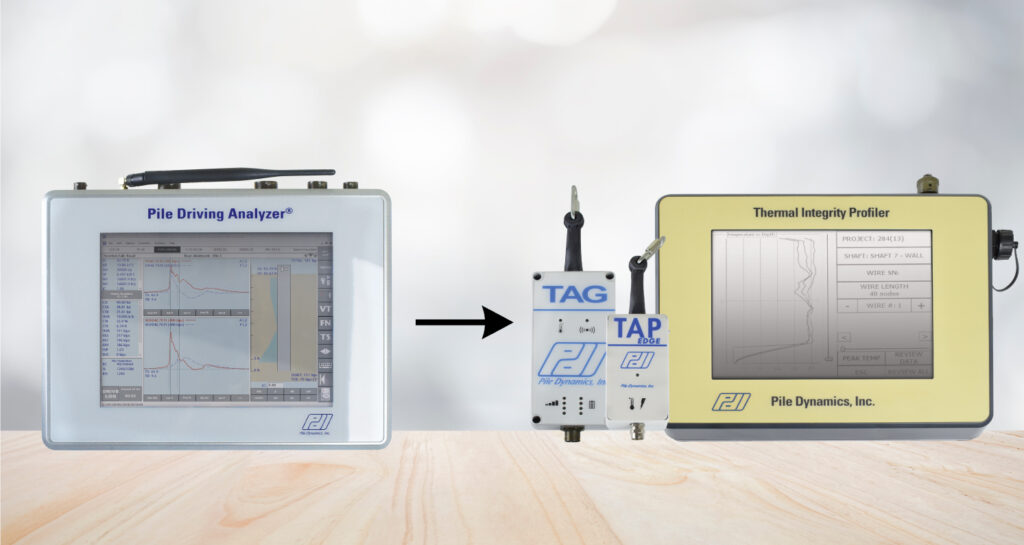

Thermal Integrity Profile Evaluator (TIP™)

- Evaluates concrete quality inside and outside the reinforcing cage

- Reveals necking or inclusions, bulges, variations in concrete cover, shape of shaft and cage alignment

- Accelerates construction with tests conducted during concrete curing

- Real time data review via PDI ATLAS™ Secured Cloud Services

PDI’s Thermal Integrity Profiler (TIP) uses NIST traceable thermal sensors to measure temperature changes during concrete curing, to identify potential voids or anomalies. TAG and TAP Edge boxes are connected to the thermal wire cables at the top of the shaft to collect and send thermal data to PDI Atlas Secure Cloud Services where data can be reviewed in real-time onsite or remotely. Learn more about TIP at https://www.pile.com/products/tip/

Investing in a PDA system may have a sooner return than expected. Learn about the income generators from the Pile Driving Analyzer. https://www.pile.com/products/pda/